Comprehensive Guide to Fruit Sorting and Washing Machines

Fruit sorting and washing machines are essential equipment in the food processing industry, specifically in facilities that handle fruit and vegetable sorting, grading, and washing. These machines not only streamline the processing but also enhance the hygiene and quality of the produce. Here, we’ll break down the different types of fruit sorting machines, washing equipment, and the technical features they offer, which vary depending on processing needs, from small-scale operations to industrial settings.

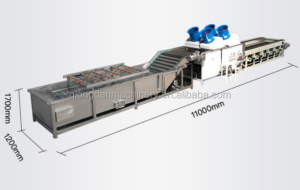

1. Plastic Crate Washing Machine

Plastic crate washing machines are designed for cleaning crates, trays, and baskets used for storing and transporting fruits, vegetables, seafood, and other food products. These machines are commonly found in central kitchens, fast-food chains, and logistics centers where cleanliness and sanitation are crucial.

Washing Modes

The washing machine includes four washing modes to ensure efficient cleaning:

- Pre-washing: Soaks crates, softening dirt and attachments.

- Main washing: Utilizes high-pressure water to clean.

- Rinsing: Reuses clean water from previous stages.

- Final washing: Employs fresh water for a thorough wash.

Technical Features and Comparison

| Features | Description |

|---|---|

| Material | Constructed from 304 stainless steel for durability and rust resistance |

| Water Recycling | Circulates water from previous modes to reduce water usage |

| High-Pressure Pump | Allows full cleaning without chemicals |

| Power-Off Protection | Prevents dry heating if water levels are low |

| Temperature Control | Each water tank has independent temperature control for efficiency |

| Nozzle Rotation | Offers 360° cleaning coverage |

| Disassembly for Cleaning | Connection parts can be removed for easy maintenance |

2. Fruit Sorting Machines

Fruit sorting machines are used to grade fruits by size, weight, or shape, improving quality by separating damaged or undersized produce. Two main types include rolling rail and weight grading fruit sorting machines.

Types of Fruit Sorting Machines

| Sorting Machine Type | Description | Capacity |

|---|---|---|

| Rolling Rail Sorting Machine | Uses spiral tracks with rollers for size-based sorting, suitable for apples, onions, and strawberries. | 1-20 tons/hour |

| Weight Grading Machine | Measures the weight of produce using load cells for precise categorization by weight. | 120 pcs/min |

| Diameter-Based Sorting Machine | Gradually increases belt spacing to sort by fruit diameter. Suitable for delicate produce like kiwi and litchi. | 0.5-3 tons/hour |

Rolling Rail Fruit Sorting Machine

The rolling rail sorting machine uses rotating spiral tracks and rollers for accurate sorting based on fruit size. Fruits tumble freely on rollers, ensuring they are evenly exposed for better sorting accuracy.

Technical Specifications and Model Comparison

| Model | Power (KM) | Capacity (T/H) | Dimensions (mm) |

|---|---|---|---|

| GXJ-2 | 0.55 | 1-2 | 3000×600×1200 |

| GXJ-5 | 0.75 | 2-5 | 3500×700×1200 |

| GXJ-10 | 1.5 | 5-10 | 4000×850×1200 |

| GXJ-15 | 2.2 | 10-15 | 5000×1000×1200 |

| GXJ-20 | 3.0 | 15-20 | 6000×1200×1200 |

Features

- High Accuracy: Sorting accuracy up to 1mm with minimal bruising to produce.

- Stainless Steel Structure: Provides durability and corrosion resistance.

- Adjustable Components: Sprinklers, dump tanks, and waste collection are customizable.

- Efficient Design: Uses a rolling and revolution design to prevent damage during sorting.

Fruit Weight Grading Machine

The weight grading machine sorts fruit by weight, beneficial for products that require precise categorization, such as apples, mangoes, and other uniformly-sized fruits.

Technical Specifications

| Parameter | Details |

|---|---|

| Sorting Product | Whole fruits and vegetables |

| Weight Range | 1-3000g |

| Sorting Speed | Up to 120 pcs/min |

| Accuracy | ±5-10g |

| Conveyor Height | 750+60mm adjustable |

| Power Supply | Single phase AC220V |

| Material | SUS304 stainless steel |

Features

- High Precision: Load cells provide accurate weight measurements.

- Multi-stage Sorting: Allows classification into multiple weight categories.

- Data Management: Equipped with USB data output for tracking and reporting.

- Touch Screen Operation: User-friendly 8-inch display for ease of use.

3. Vegetable and Fruit Sorting Machine

The QD series vegetable and fruit sorting machine is ideal for grading a wide variety of produce, including fruits like apples, potatoes, and onions. This machine uses diameter control for accurate grading based on the size of the produce.

Working Principle

Working Principle

The machine operates with a uniform walking silica gel conveyor belt that gradually increases belt distance, sorting fruits by diameter.

Technical Comparison

| Model | Track Quantity | Grading Quantity | Capacity (T/H) | Machine Size (m) | Weight (kg) |

|---|---|---|---|---|---|

| QDFJ-2-9 | 9 | 3-6 adjustable | 0.5-1 | 2.2×0.7×1.1 | 110 |

| QDFJ-2-11 | 11 | 3-6 adjustable | 1-1.5 | 2.2×0.7×1.1 | 110 |

| QDFJ-2-13 | 13 | 3-6 adjustable | 1-1.5 | 2.2×0.7×1.1 | 110 |

| QDFJ-2-15 | 15 | 3-6 adjustable | 1.5-3 | 2.2×1.3×1.1 | 260 |

Features

- Multi-functional Design: Can grade a wide variety of fruits and vegetables.

- Soft Contact Parts: Prevents bruising with food-grade silicone belts.

- Adjustable Grades: Both the grade quantity and size range are customizable.

- Safety Features: Includes automatic reverse protection to prevent operational errors.

4. Fruit and Vegetable Frying Machine

This advanced machine allows fruits and vegetables to be fried, de-oiled, and conveyed in a compact structure. Widely used in snack processing, it offers PLC-controlled operations and includes several models suitable for various production capacities.

Technical Specifications and Model Comparison

| Model | Capacity (kg/h) | Power (kw) | Temperature Range | Dimensions (mm) |

|---|---|---|---|---|

| GWF-30 | 100-300 | 5 | 0-300°C | 3000×1350×2250 |

| GWF-40 | 100-500 | 6.5 | 0-300°C | 4000×1350×2250 |

| GWF-50 | 500-1000 | 6.5 | 0-300°C | 5000×1350×2250 |

| GWF-60 | 600-1200 | 6.5 | 0-300°C | 6000×1350×2250 |

| GWF-80 | 1000-2000 | 8.5 | 0-300°C | 8000×1350×2250 |

Conclusion

Selecting the right machine is essential in food processing industries for streamlining operations, maintaining hygiene, and ensuring product quality. Each machine—from washing crates to frying fruits—offers unique functionalities tailored to various production demands. Making an informed choice based on production requirements and desired technical features is crucial to achieving optimal efficiency.